Cocoa

There is a correlation between chocolate consumption and the number of Nobel Prize winners per nation

General information

“Cocoa” refers to both the plant (with the botanical name Theobroma cacao) and the famous hot beverages.

The first cultivation of coca was carried out around 1500 BC in Central America. Around 300 AD the trade good became a cultural symbol and means of payment for the Maya. This lasted until the Aztecs. With the “Discovery of the New World”, cocoa gained a new meaning. The Spanish conquerors brought cocoa consumption from Central America to Europe. From Spain consumption spread via Italy to France. Cocoa was consumed as an infused beverage among the nobility and the upper bourgeoisie. Due to economic developments in the 19th century cocoa became affordable for the general public. Today, a variety of products such as cocoa powder, cocoa mass and cocoa butter as well as various chocolate products are made from the cocoa plant.

Growing regions

Cocoa is grown exclusively in the tropics, with West Africa being the largest producer, followed by South America and Asia. Cocoa plantations respond particularly well to relatively high temperatures of a maximum of 32°C and a minimum of 18°C, which is why the cultivation areas are spread around the equator. Another important factor for the global cocoa yield is the annual rainfall, which should ideally occur abundantly –between 1500 and 2000 mm per annually – and well distributed throughout the year. Dry periods with less than 100 mm should also not last longer than three months. As well as plenty of rainfall, a very humid climate is also crucial for the growth of the cocoa fruit. The relative humidity in the growing regions ranges from 100% during the day to 70% at night. Ultimately, light and shadow also play a major role for cocoa. In nature, cocoa is primarily found in the Amazon region.

Den verschiedenen Anbaugebieten lassen sich auch unterschiedliche Kakaosorten zuordnen. Allgemein gilt: Hunderte von Kakaobaumsorten stammen von wenigen Urarten ab.

Criollo: natürliches Vorkommen nördlich und westlich der Anden (Venezuela); feinstes Aroma, allerdings anfällig für Schädlinge

Forastero: Vorkommen im Amazonasbecken; gilt als robust und ertragreich; macht bis zu 95 % des weltweiten Kakaohandels aus

Trinitario: Kreuzung aus Criollo und Forastero; entstanden im 18. Jahrhundert in Trinidad

Weitere Sorten sind beispielsweise Arriba (verwandt mit Criollo) und Amelonado (östliches Amazonasbecken).

Cultivation and harvest

Over 90% of the world’s cocoa farmers can be classified as smallholders as they cultivate small fields of up to five hectares. As already mentioned, in addition to temperatures and precipitation, light and shade conditions also play a key role. The Amazon region offers good conditions, for example, which has a relatively large supply of natural shade due to its tall trees. Sufficient shade is indispensable, not only in the early years of a cocoa tree, but also crucial for soil quality. Pure monocultures without shade trees often lead to poor soil conditions, which in turn result in lower yields.

Suitable shade trees are mainly young banana or corn trees, as well as older guava or mango trees as well as coconut or oil palms. The cocoa trees themselves grow up to 15 m tall, but they are usually cultivated to a height of 3–4 m to facilitate harvesting. Cocoa trees bear the first fruits after about 4 years. The full yield can be harvested after up to 10 years. In total, cocoa trees bear fruit for up to 50 years. The cocoa trees bear fruit, leaves, buds and flowers throughout the year. Pollination by small flies is a massive limiting factor for yields. In some areas, natural pollination no longer takes place. This is then carried out by hand. The plants themselves are also very sensitive and susceptible to drought, diseases and pests. Therefore, the cultivation of cocoa plants requires a high level of labor intensity. Harvesting is also labour intensive and is done by hand. The fruit, which weighs about 500 g, is cut from the trees with machetes or sticks.

From fruit to product

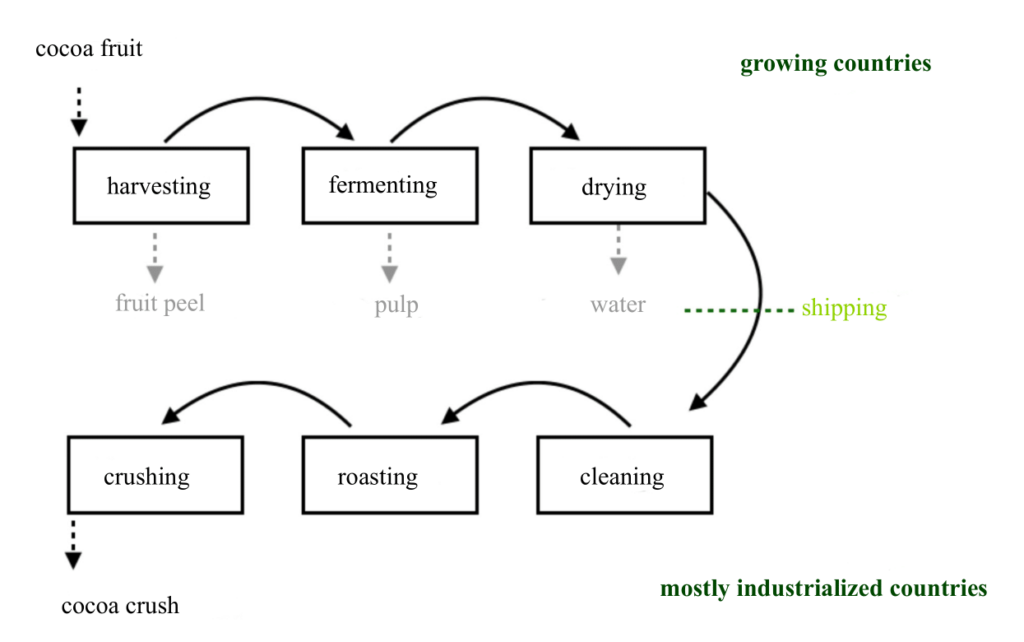

First, cocoa nibs are extracted from the cocoa fruit. This process requires six steps. While harvesting, fermenting and drying take place in the growing countries, the processes of cleaning, roasting and crushing often take place in the receiving countries. Immediately after the cocoa fruit is harvested, the cocoa bean with the pulp is separated from the fruit shell. The latter is generated as a waste product. In the next step the beans are fermented immediately. This process ensures the high quality of the subsequent products. Essentially, four objectives are achieved: the pulp is completely separated from the bean, aromatic substances are formed, the brown coloration sets in and by killing the seedlings, the beans can be stored better and longer.

During the drying process, the residual moisture content is reduced from 60% to 6%. A large proportion of the beans are then shipped to industrialized countries. There they are cleaned. In the penultimate step, the beans are sorted according to size for even roasting. Different roasting processes and times are used depending on the final use of the beans. In the final step of the process – crushing- the beans must be cooled immediately after roasting. The process is carried out in two different ways: The beans are crushed either by rolling or by spinning them onto a plate. The resulting crushed cocoa can now be further processed into cocoa powder or chocolate for example.

Certification

In the area of certification, two major groups of interest are actively engaging in the cocoa industry: the Rainforest Alliance (RA) & UTZ Certification and Fairtrade. Both organizations promote a premium for sustainably produced cocoa per ton, but at Fairtrade, it is more than three times higher than at RA & UTZ. In addition, Fairtrade protects cocoa producers through a fixed minimum price, which is designed to provide additional support for families living on the poverty line during the sometimes-extreme fluctuations in the world’s market prices. In contrast, the RA & UTZ certification stands for long-term nature conservation programs in regions where the production of raw materials damages the ecosystem. Nevertheless, these two organizations have contributed, among other things, to increasing the numbers of sustainably produced cocoa used for sweets sold in Germany to 79%.

Sustainability

One way to make cocoa farming more sustainable is through agroforestry systems. These include not only cocoa but also taller shade trees or other crops. This not only prevents the deforestation necessary to meet the global demand for cocoa, but also significantly improves soil quality as it is no longer exposed to light constantly. One disadvantage of agroforestry in comparison to monoculture is lower yield. Another problem are the conditions the families involved in cocoa production live in. Most of them are severely affected by poverty, which is why they prefer less sustainable farming methods. Therefore, agroforestry systems are unattractive for farmers without support and a sustainability seal.